In the rapidly evolving landscape of manufacturing, the advent of cutting-edge technologies is continuously redefining industry standards. One such technological marvel that promises to revolutionize manufacturing is AMS39K. This advanced manufacturing system integrates the latest in artificial intelligence, machine learning, and the Internet of Things (IoT) to create an environment that is both highly automated and exceptionally efficient. In this article, we will explore the intricacies of AMS39K, its features, benefits, and the transformative impact it is set to bring to the manufacturing sector.

What is AMS39K?

AMS39K, short for Advanced Manufacturing System 39K, is a groundbreaking system designed to enhance productivity, precision, and efficiency in manufacturing processes. The system’s sophisticated integration of modern technologies aims to streamline operations, reduce errors, and elevate the overall quality of production. As industries continue to embrace the era of Industry 4.0, systems like AMS39K are at the forefront, driving innovation and competitive advantage.

Key Features of AMS39K

1. Artificial Intelligence and Machine Learning Integration

One of the standout features of AMS39K is its incorporation of artificial intelligence (AI) and machine learning (ML). These technologies are crucial for optimizing production processes. AI algorithms can analyze vast amounts of data to identify patterns and trends that human operators might miss. ML, on the other hand, enables the system to learn from historical data, improving its efficiency and effectiveness over time. This continuous learning process allows AMS39K to adapt to changing conditions and requirements, ensuring consistent high performance.

2. IoT Connectivity

The AMS39K system is equipped with IoT capabilities, which facilitate real-time monitoring and data collection. IoT devices embedded within the system provide detailed insights into various aspects of the manufacturing process, including machine performance, energy consumption, and production output. This connectivity enables better decision-making by providing operators with up-to-date information, thereby enhancing operational efficiency and reducing downtime.

3. Precision and Flexibility

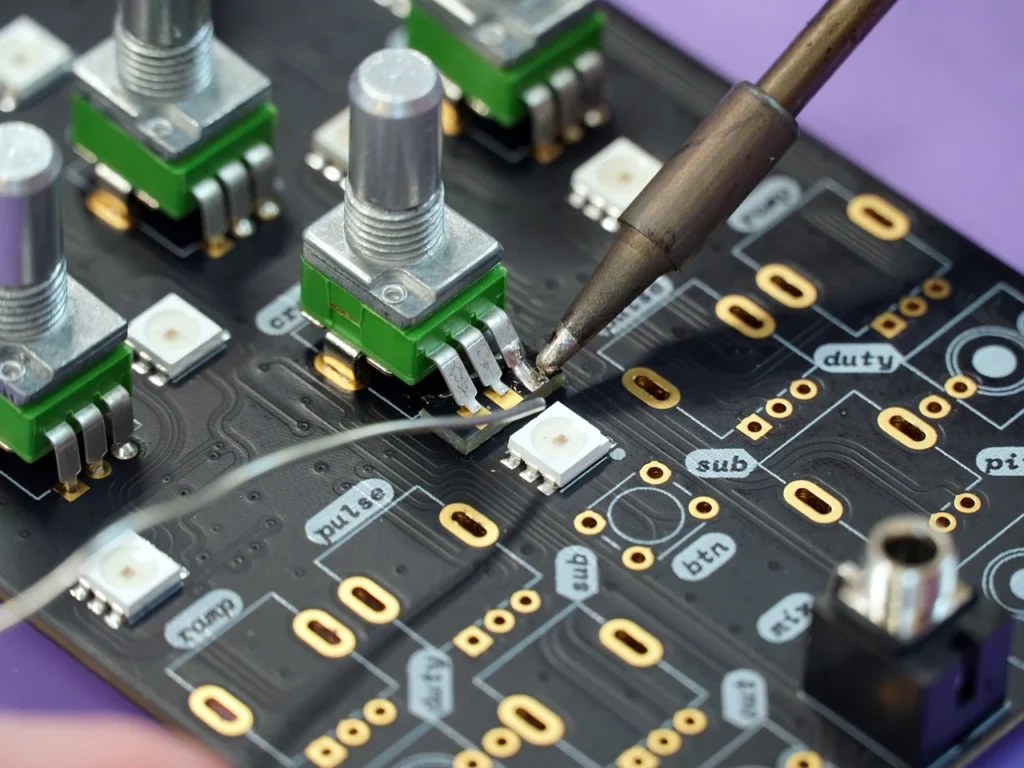

AMS39K is designed to deliver high precision in manufacturing, significantly reducing errors and waste. Its flexible architecture allows it to adapt to various production requirements, making it suitable for a wide range of industries. Whether it’s the automotive sector, electronics manufacturing, or consumer goods production, AMS39K can be tailored to meet specific needs, ensuring optimal performance across different applications.

4. User-Friendly Interface

Despite its advanced capabilities, AMS39K features an intuitive, user-friendly interface. This design consideration minimizes the learning curve for operators, enabling them to quickly master the system’s functionalities. The interface provides clear, actionable insights and easy-to-navigate controls, making it accessible even to those with limited technical expertise. This user-centric approach ensures that manufacturers can integrate AMS39K into their existing workflows with minimal disruption.

Benefits of Implementing AMS39K

1. Increased Productivity

The advanced automation and optimization capabilities of AMS39K significantly boost productivity. By streamlining production processes and reducing the need for manual intervention, the system enables manufacturers to achieve higher output levels without compromising on quality. This increase in productivity can lead to substantial competitive advantages, allowing companies to meet growing demand more effectively.

2. Cost Savings

AMS39K’s predictive maintenance feature is a key contributor to cost savings. By monitoring equipment in real-time and predicting potential failures before they occur, the system minimizes downtime and reduces maintenance costs. Additionally, the system’s precision reduces material wastage, further contributing to overall cost efficiency. These savings can be redirected towards other critical areas of the business, enhancing profitability.

3. Enhanced Quality Control

Quality control is a critical aspect of manufacturing, and AMS39K excels in this area. The system’s real-time quality monitoring ensures that defects are detected and addressed promptly, leading to higher product quality and customer satisfaction. By maintaining consistent quality standards, manufacturers can build stronger brand reputations and foster customer loyalty.

4. Scalability

AMS39K is designed with scalability in mind. Its modular architecture allows manufacturers to expand their production capacities as needed. Whether scaling up to meet increased demand or adapting to new market opportunities, AMS39K provides the flexibility to grow with the business. This scalability ensures that the system remains a valuable asset as the manufacturing landscape evolves.

The Transformative Impact of AMS39K

The introduction of AMS39K is set to revolutionize the manufacturing industry. By integrating advanced technologies into the production process, it paves the way for smart factories and the full realization of Industry 4.0. This transformation not only enhances operational efficiency but also opens up new opportunities for innovation and growth.

1. Smart Factories

AMS39K is a cornerstone in the development of smart factories, where machines, systems, and humans work together seamlessly. In a smart factory, data flows continuously between different components, enabling real-time adjustments and optimizations. AMS39K’s IoT connectivity and AI capabilities make it an ideal candidate for such environments, facilitating dynamic and responsive manufacturing processes.

2. Innovation and Growth

With AMS39K, manufacturers can explore new avenues for innovation. The system’s advanced data analytics capabilities provide deep insights into production processes, uncovering opportunities for improvement and innovation. By leveraging these insights, companies can develop new products, optimize existing ones, and improve their overall market positioning. This focus on innovation drives growth and ensures long-term success in a competitive marketplace.

Conclusion

AMS39K represents a significant leap forward in advanced manufacturing systems. Its combination of AI, IoT, and precision engineering positions it as a critical enabler of modern manufacturing practices. As industries continue to embrace digital transformation, AMS39K stands out as a vital tool for manufacturers looking to stay ahead of the curve and drive their businesses toward a more efficient, productive, and innovative future.

In summary, AMS39K is not just an advanced manufacturing system; it is a transformative technology that promises to redefine the manufacturing landscape. By embracing AMS39K, manufacturers can unlock new levels of productivity, efficiency, and quality, positioning themselves for success in the ever-evolving world of Industry 4.0.